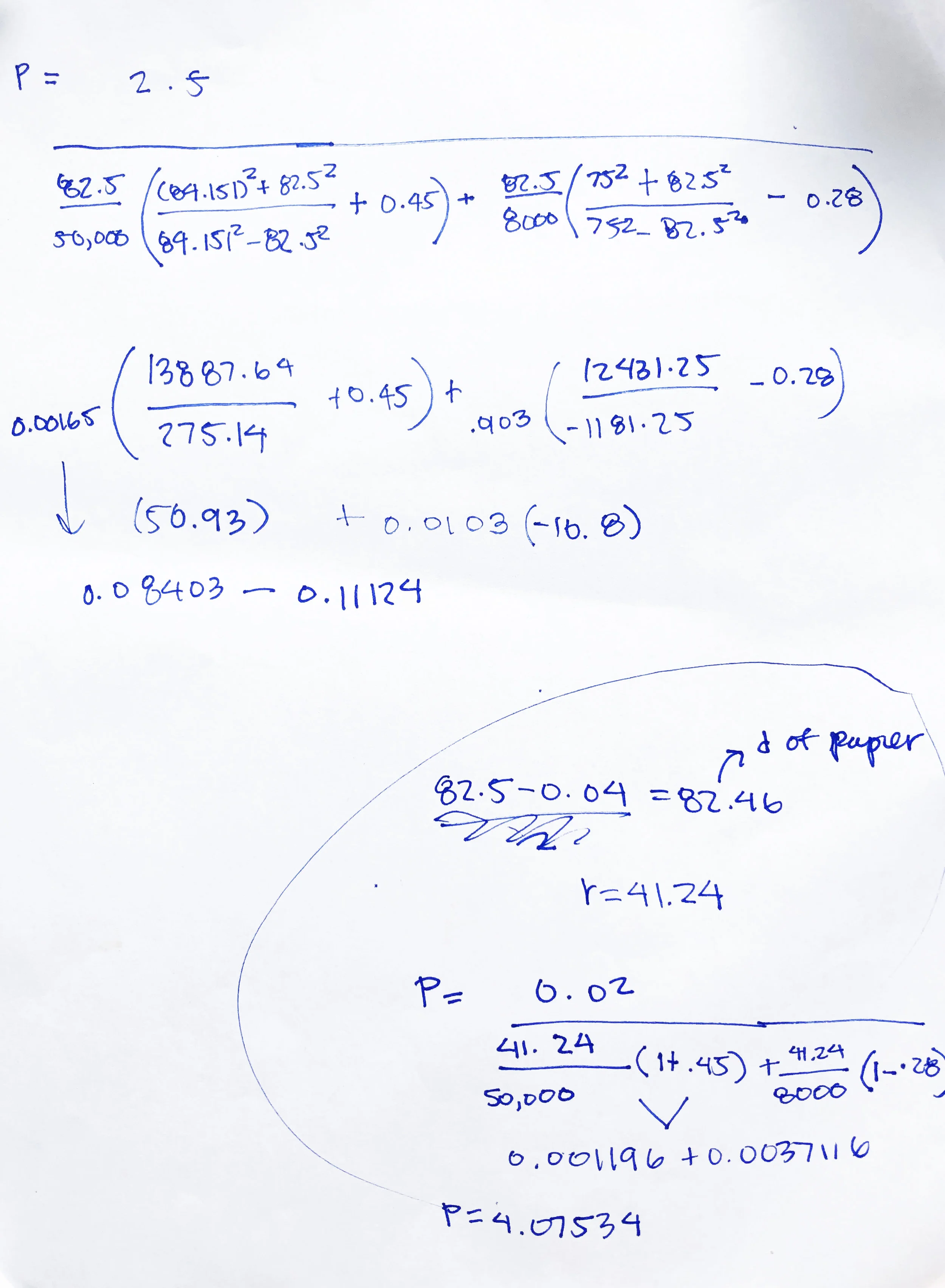

Tolerance stack -

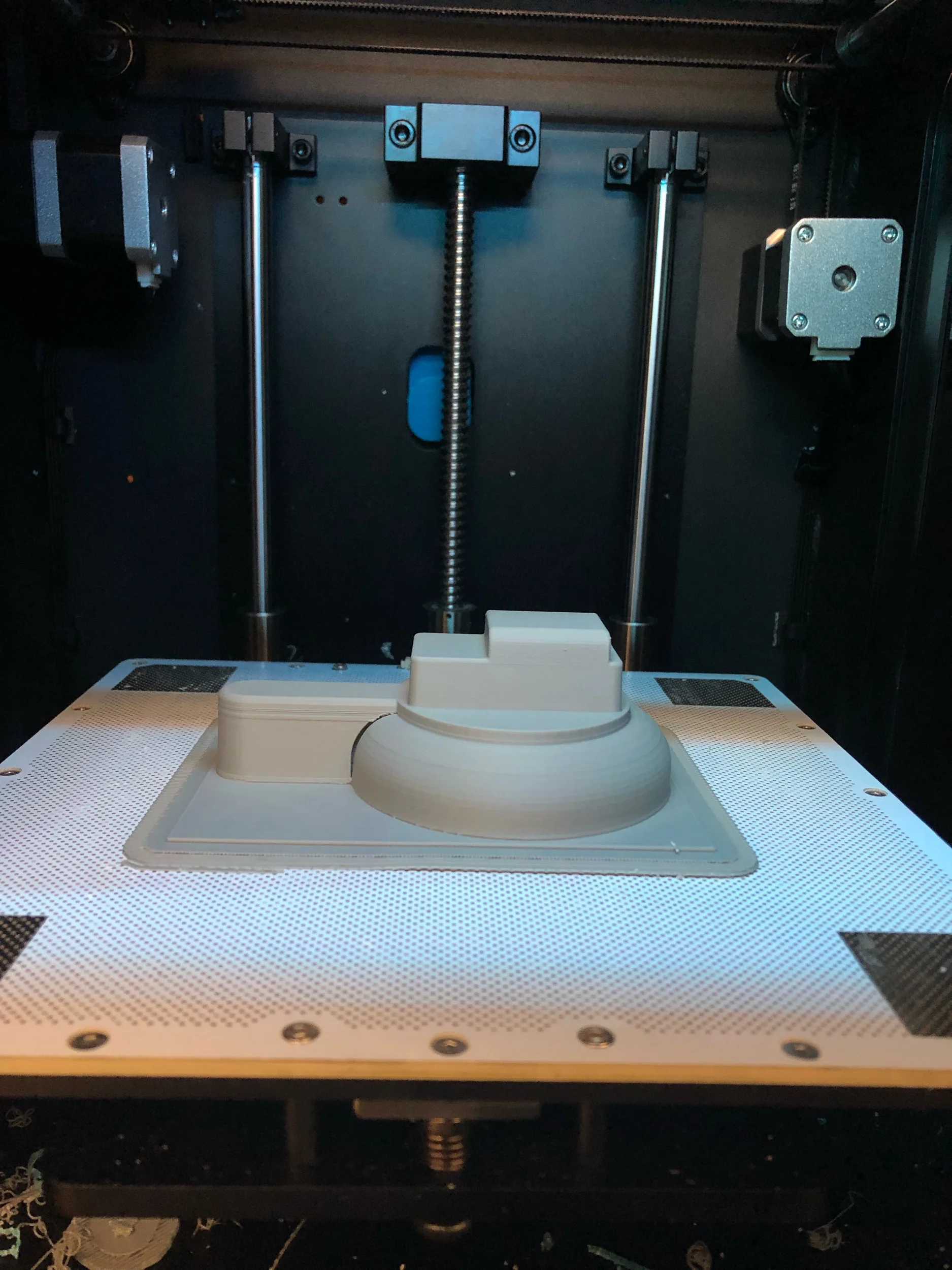

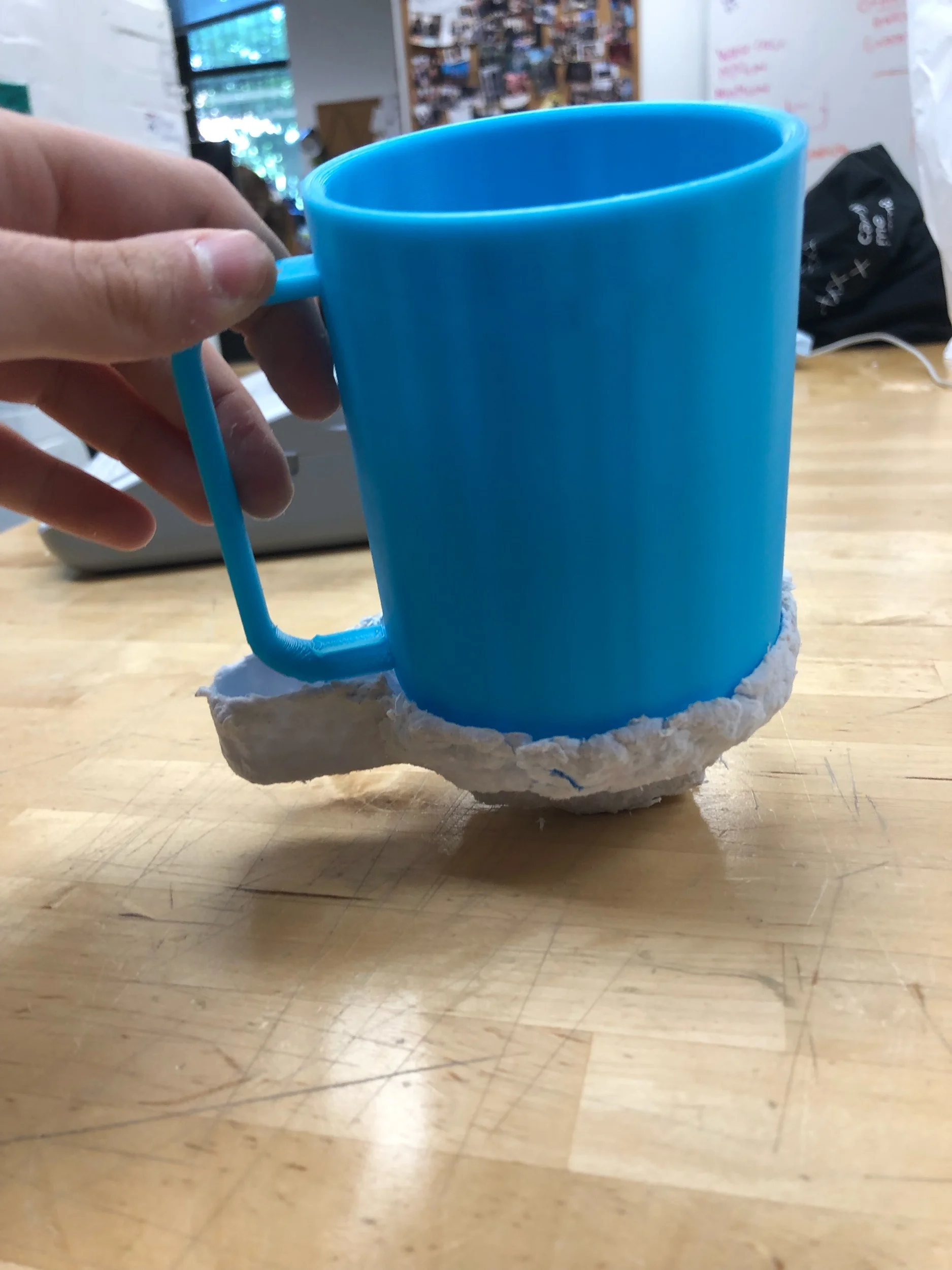

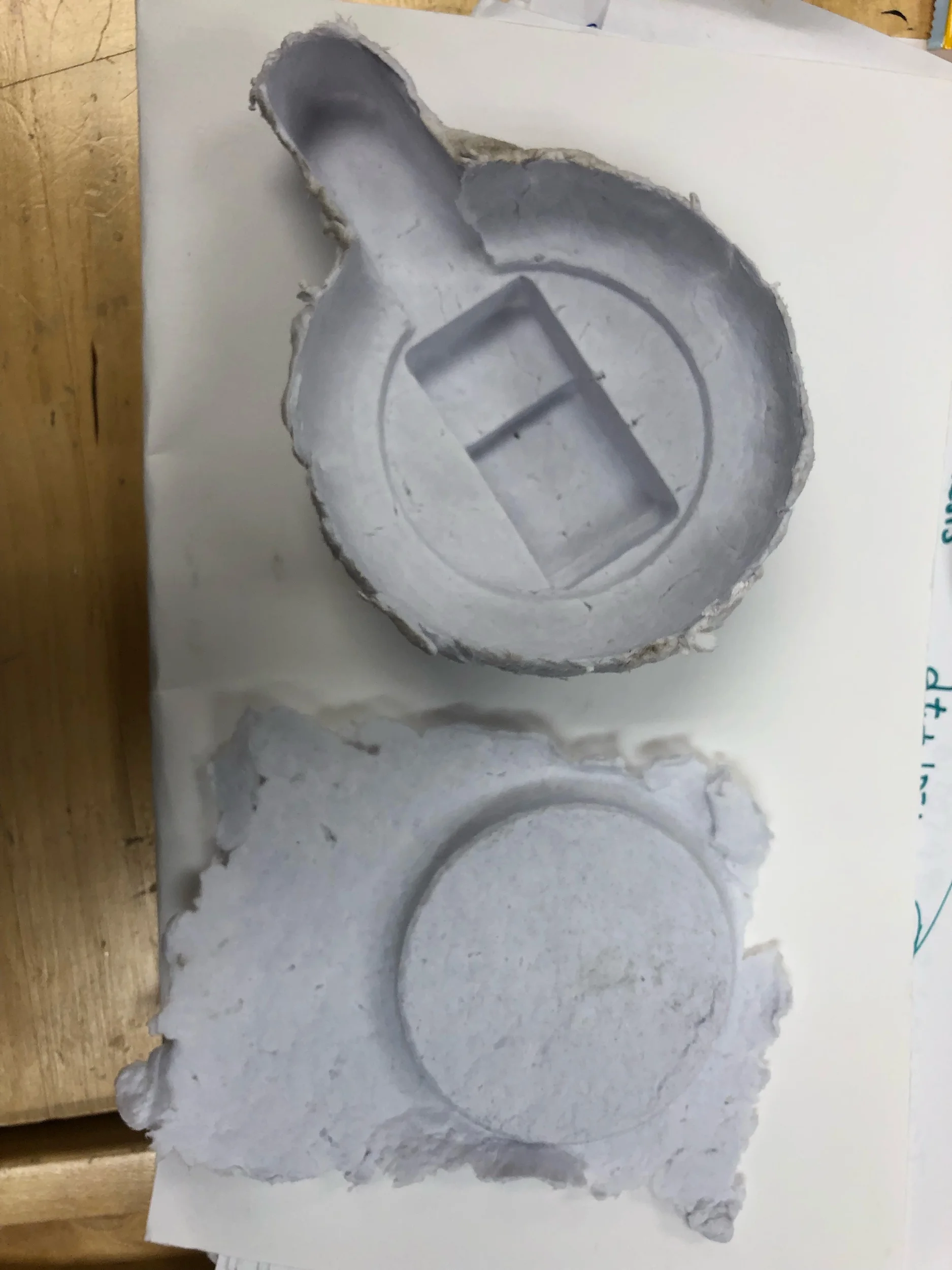

Dimensions of box to slip fit with suction, diameter of plug to interface with mug

Assumptions

Box top and bottom have a max distance of 0.006mm to achieve Apple’s signature suction

opposite sides will deviate equally

Min. ID of mug > 78.994mm